Screenpod - TFS1400 Flotation Separator

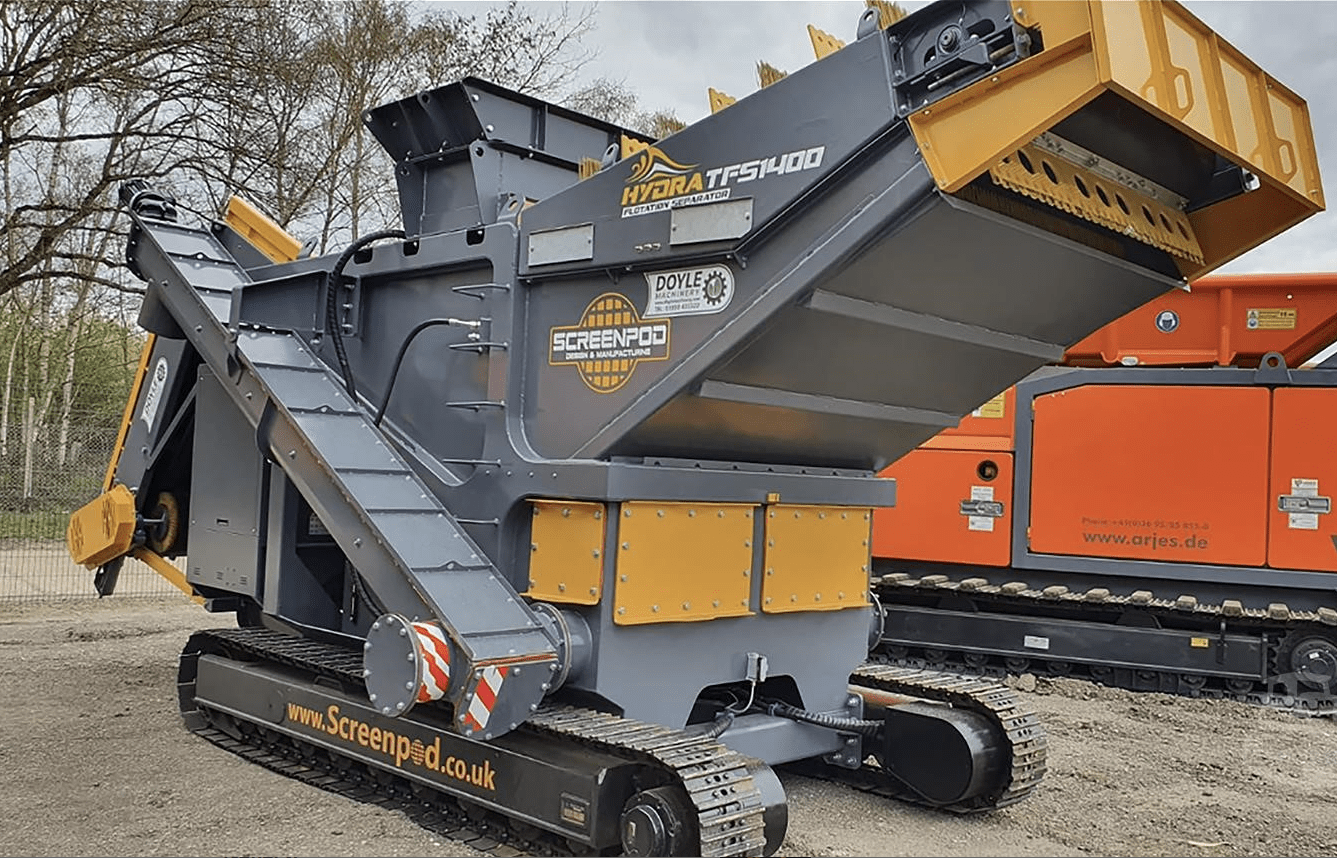

TFS1400 Hydra Flotation Separator

Available in diesel-hydraulic

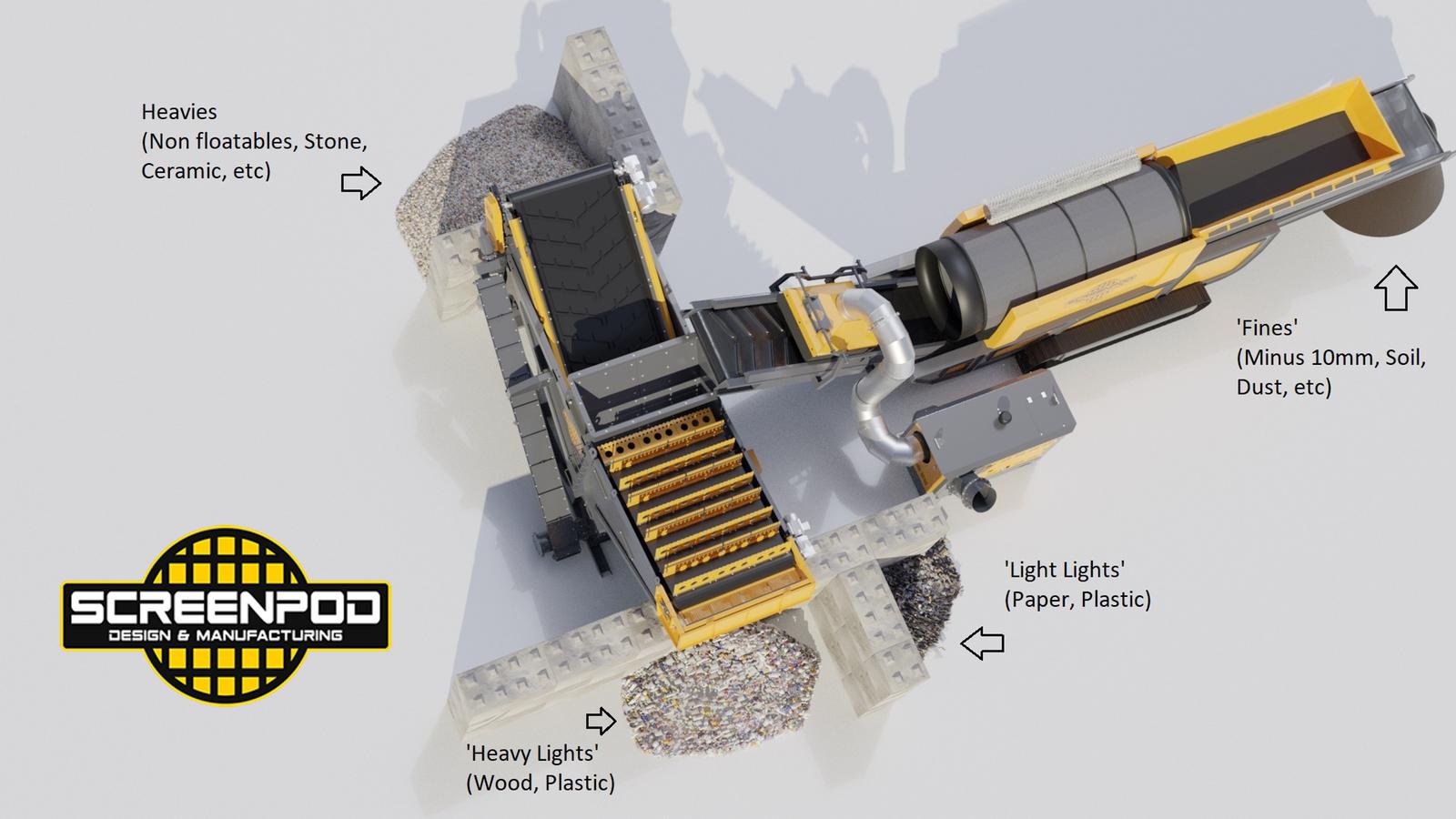

The Process:

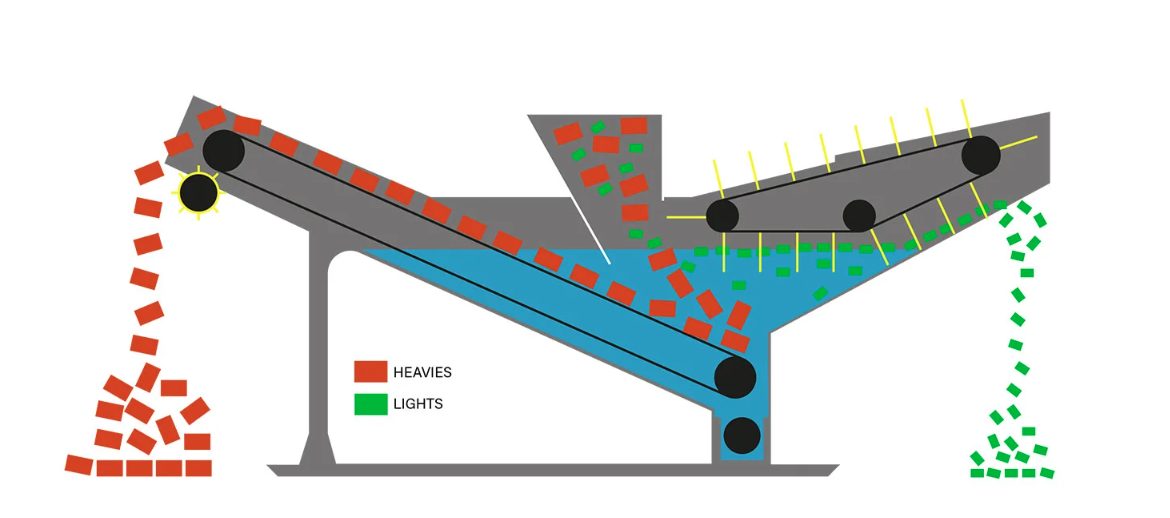

The machine is known as a flotation separator, which can separate low density material, such as wood and plastic, from high density material, such as stone and concrete.

A mixture of heavy and lightweight material is fed into the top of the machine via a conveyor. As the material falls into the water, the buoyancy of the water causes the lightweight, low-density material to float to the top, whilst the heavyweight, high density material, sinks to the bottom.

A conveyor at the base of the tank takes the heavy material out one side, whilst the brush conveyor skims the lightweight material off the surface of the water and takes it out the other side, thus separating the two material types from one another.

Construction & Demolition

Waste & Plastics

Waste Wood